Steaming And Sterilizing Packaging

Category:

Keywords:

Food Packaging

Material structure: BOPP, BOPET, BOPA, AL, K film, alumina PET, PE, CPP, etc.

Features

The combination of waterproof and retort-resistant materials can ensure that the packaging has sufficient high temperature resistance, drop resistance, puncture resistance and sealing strength under boiling and retort sterilization conditions (some products require reverse pressure cooling), and ensure that the outer packaging does not shrink, change color, deform, or delaminate after sterilization; thereby effectively killing microorganisms in the packaging. Extend the shelf life and make the food usable.

Main sterilization conditions

(1) <85℃ pasteurization

(2) 86-100℃ vacuum boiling sterilization

(3) 86-100℃ gas-containing boiling sterilization

(4) 100-121℃ vacuum semi-high temperature retort sterilization

(5) 121-135℃ vacuum high temperature retort sterilization.

PRODUCTION PROCESS

It has 4 high-speed electronic axis printing production lines of international brands such as BOBST and Otmar, with a printing speed of up to 400 meters per minute and 10 printing colors, which can meet the printing quality requirements of different customers. It is also equipped with dry and solvent-free composite equipment to meet the needs of customers with different functions. The finished product workshop is equipped with multiple high-speed slitting machines and various high-precision bag making machines, which can achieve 60 tons of film rolls and 5 million bags per day.

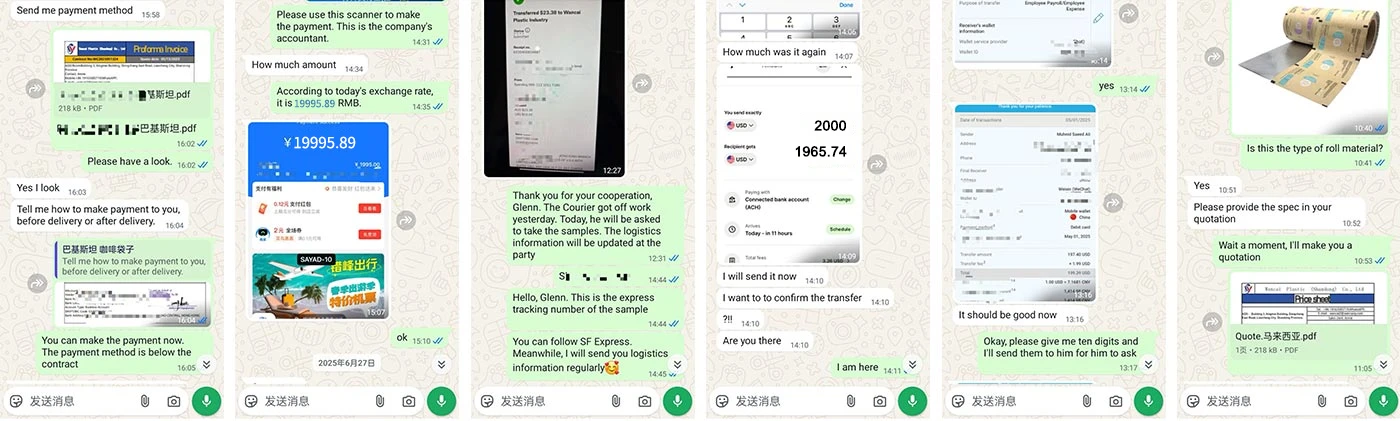

CASE

You can print up to 12 colors. As a zippered flat bag, the printing side can customize your artwork or provide your design drawings. SOME CUSTOM CASES Factory direct sales professional customization is trustworthy

CUSTOMER VISIT

You can print up to 12 colors. As a zippered flat bag, the printing side can customize your artwork or provide your design drawings. SOME CUSTOM CASES Factory direct sales professional customization is trustworthy

PACKING AND DELIVERY

The company strictly implements the PDCA cycle improvement management, constantly adopts scientific management models, adheres to the production concept of continuous improvement, pursues "excellent quality, zero defects" as the goal, and provides consumers with high-quality and stable flexible packaging products.

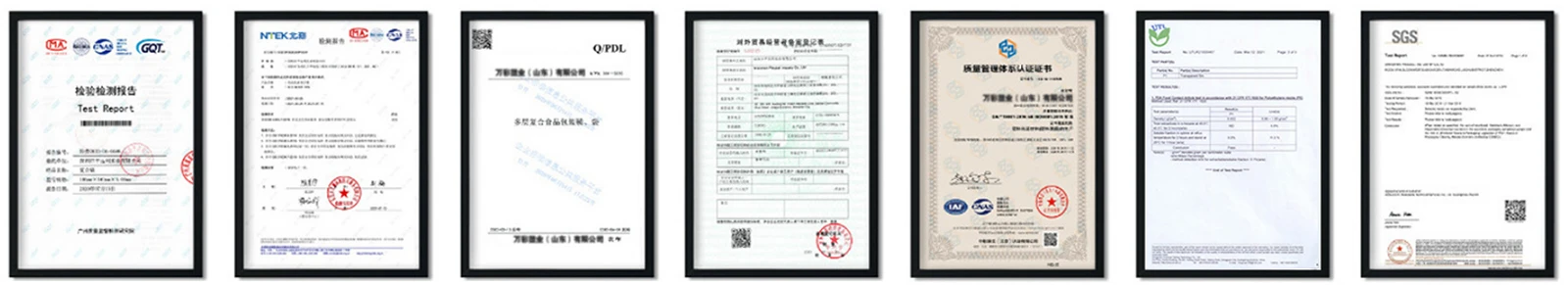

QUALIFICATIONS AND HONORS

we have management system that meets international requirements, issupervised and evaluated by third-party institutions,and is internationallyrecognized,providing more security for enterprises and escorting yourproducts.

Previous:

Next:

Related Products

Get Quote

*Contact us now, starting from the first communication!