Courier Bags

Category:

Keywords:

Daily Consumer Goods Packaging

Courier bags are bags used by the express delivery industry to package documents, receipts, materials, and goods. They are also known as express bags, mailing bags, and courier packaging bags.

Plastic courier bags made of polyethylene are commonly used, offering low cost, ease of use, and excellent waterproof properties.

In addition to major courier companies using customized courier bags, many online retailers also customize their own courier bags to create a positive impression for customers, enhance their image, and promote their products.

Categories: Courier bags are categorized by material into courier plastic bags, courier document envelopes, courier bubble bags, courier bone bags, and courier woven bags.

1. Courier Plastic Bag Material: Low-density polyethylene (LDPE), commonly known as PE, and high-density polyethylene (HDPE), commonly known as PO. Courier plastic bags offer advantages such as low cost and light weight. The difference between PE and PO in express plastic bags: PE offers greater transparency and softness, and produces brighter printed colors; PO has superior mechanical properties. In China, express bags are generally made primarily of PE, while overseas, a combination of PE and PO is generally used.

Polyethylene express bags are divided into two main categories on the market: virgin and recycled.

2. Express document seals: These are typically made of gray-based white paper, white cardboard, or kraft paper. The express delivery industry generally uses paper weighing between 200 g/m2 and 450 g/m2. Express document seals offer the advantages of being flatter and less prone to folding than plastic bags.

3. Express bubble bags: These are transparent, flexible packaging bags composed of an air-filled middle layer of air-cushion film. They are primarily used in the express delivery industry for packaging small, fragile, and delicate goods. They contain shock-absorbing bubble film, which contains countless tiny bubbles, resulting in a lightweight, flexible design. They offer excellent shock absorption and impact resistance, and are also non-toxic, odorless, moisture-proof, and corrosion-resistant.

4. Express Bone Bag Material: Bone bags (also known as dense bags, including free-standing bags, sealed bags, ziplock bags, and ziplock bags) are resealable plastic bags made from polyethylene (LDPE) and high-pressure linear polyethylene (LLDPE) through blown film molding and hot-cut machine-made bags. Bone bags can be used for both internal and external packaging of various small items. Ziplock bags made from food-grade raw materials can be used to store various snacks, tea, seafood, etc., and are moisture-proof, waterproof, insect-proof, and prevent items from spilling.

5. Express Woven Bags: Also known as Snakeskin Bags. This is a type of plastic used for packaging. Its raw materials are generally polyethylene, polypropylene, and other chemical plastics. Woven bags are generally white or off-white, non-toxic and odorless, and generally pose little harm to the human body. Although made from various chemical plastics, they are highly environmentally friendly and can be recycled easily. They are primarily used for packaging and packaging of various items and have a wide range of industrial applications.

PRODUCTION PROCESS

It has 4 high-speed electronic axis printing production lines of international brands such as BOBST and Otmar, with a printing speed of up to 400 meters per minute and 10 printing colors, which can meet the printing quality requirements of different customers. It is also equipped with dry and solvent-free composite equipment to meet the needs of customers with different functions. The finished product workshop is equipped with multiple high-speed slitting machines and various high-precision bag making machines, which can achieve 60 tons of film rolls and 5 million bags per day.

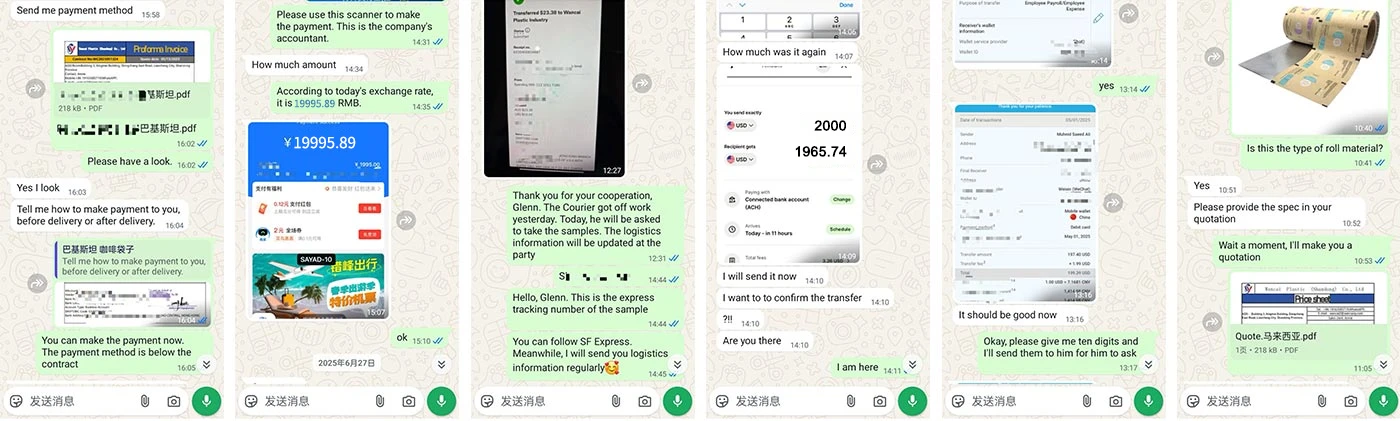

CASE

You can print up to 12 colors. As a zippered flat bag, the printing side can customize your artwork or provide your design drawings. SOME CUSTOM CASES Factory direct sales professional customization is trustworthy

CUSTOMER VISIT

You can print up to 12 colors. As a zippered flat bag, the printing side can customize your artwork or provide your design drawings. SOME CUSTOM CASES Factory direct sales professional customization is trustworthy

PACKING AND DELIVERY

The company strictly implements the PDCA cycle improvement management, constantly adopts scientific management models, adheres to the production concept of continuous improvement, pursues "excellent quality, zero defects" as the goal, and provides consumers with high-quality and stable flexible packaging products.

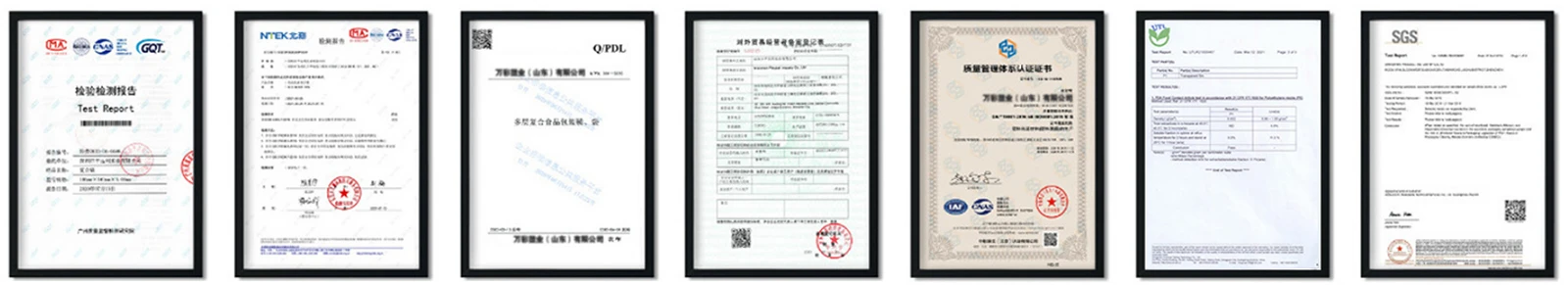

QUALIFICATIONS AND HONORS

we have management system that meets international requirements, issupervised and evaluated by third-party institutions,and is internationallyrecognized,providing more security for enterprises and escorting yourproducts.

Previous:

Next:

Related Products

Get Quote

*Contact us now, starting from the first communication!