Chocolate Packaging Bag

Category:

Keywords:

Food Packaging

Aluminum foil: It has the characteristics of moisture-proof, light-proof and heat-insulating. It can effectively prevent chocolate from melting due to moisture, and also avoid light damage to chocolate. Aluminum foil packaging can also well preserve the aroma of chocolate and prevent it from escaping.

Paper products: It is environmentally friendly and can add a delicate texture to chocolate. Commonly used papers include coated paper, white cardboard, etc. These papers are water-resistant, oil-resistant and acid-resistant, and can provide good protection. In addition, some high-value-added functional papers, such as deodorizing paper and wafer paper, are gradually being used in chocolate packaging.

Plastic: Due to its rich functions and diverse display forms, plastic packaging has gradually become one of the main choices for chocolate packaging. Plastic packaging has good moisture-proof and anti-oxidation properties, which can extend the shelf life of chocolate. In particular, cold-sealed soft packaging technology is widely used in chocolate inner packaging due to its advantages such as high speed, low odor and no pollution.

Composite materials: A new type of packaging material formed by combining multiple materials through a specific process. Common composite materials include paper-plastic composite, aluminum-plastic composite and paper-aluminum composite, etc. These composite materials combine the advantages of different materials and have excellent protective performance and display effects.

PRODUCTION PROCESS

It has 4 high-speed electronic axis printing production lines of international brands such as BOBST and Otmar, with a printing speed of up to 400 meters per minute and 10 printing colors, which can meet the printing quality requirements of different customers. It is also equipped with dry and solvent-free composite equipment to meet the needs of customers with different functions. The finished product workshop is equipped with multiple high-speed slitting machines and various high-precision bag making machines, which can achieve 60 tons of film rolls and 5 million bags per day.

CASE

You can print up to 12 colors. As a zippered flat bag, the printing side can customize your artwork or provide your design drawings. SOME CUSTOM CASES Factory direct sales professional customization is trustworthy

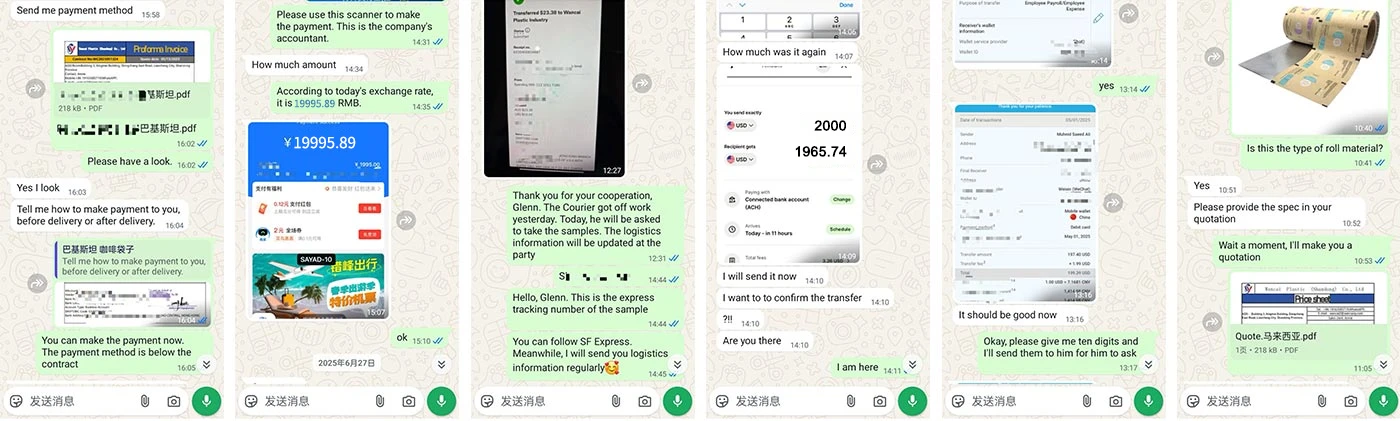

CUSTOMER VISIT

You can print up to 12 colors. As a zippered flat bag, the printing side can customize your artwork or provide your design drawings. SOME CUSTOM CASES Factory direct sales professional customization is trustworthy

PACKING AND DELIVERY

The company strictly implements the PDCA cycle improvement management, constantly adopts scientific management models, adheres to the production concept of continuous improvement, pursues "excellent quality, zero defects" as the goal, and provides consumers with high-quality and stable flexible packaging products.

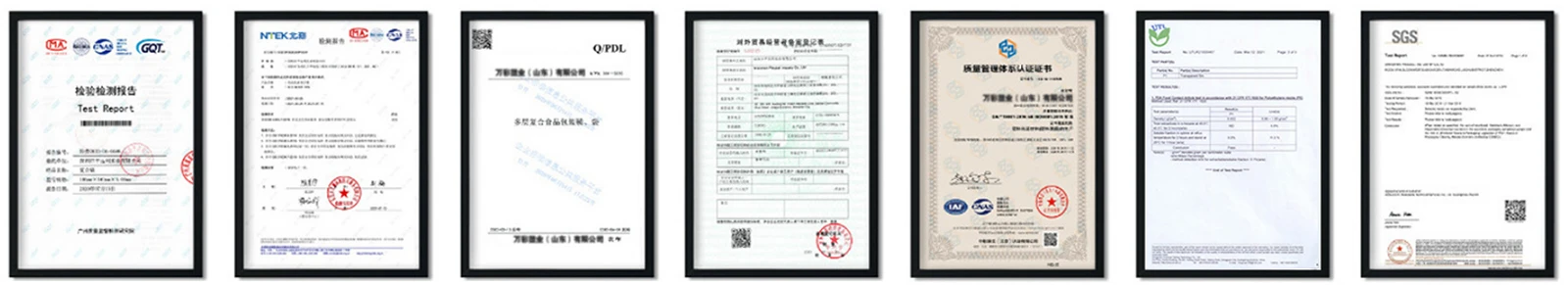

QUALIFICATIONS AND HONORS

we have management system that meets international requirements, issupervised and evaluated by third-party institutions,and is internationallyrecognized,providing more security for enterprises and escorting yourproducts.

Previous:

Related Products

Get Quote

*Contact us now, starting from the first communication!