Cement Bags

Category:

Keywords:

Special Product Packaging

Cement bags are specialized containers used for packaging and transporting cement, primarily available in bulk and bagged forms. Bagged cement is typically standardized with a fixed net weight (e.g., 50 kg/bag). Bag types must comply with the national standard GB/T 9774-2020. Currently, only square-bottom valve bags are available, eliminating traditional seam-bottom bags.

Materials and Structure

Plastic cement packaging bags: Made from a composite of polypropylene or polyethylene film woven fabric and kraft paper, they are waterproof, moisture-proof, and high-strength, minimizing cement loss and conserving wood resources.

Paper-plastic composite bags: They must meet requirements for alkali resistance and moisture resistance to ensure they are not damaged during transportation.

National Standards and Testing

GB/T 9774-2020: Specifies technical requirements for cement bags, including classification, specifications, durability testing (e.g., a 1m drop test), and moisture resistance. Testing Items: These include tensile strength, printing quality, and mass per unit area, ensuring the bags can withstand the impact of transport when loaded with 50kg of cement.

Application and Environmental Significance

Environmental Reform: Following the implementation of the new standard, the square-bottom valve bag format solves the serious environmental issue of dust spraying during filling with traditional seam-bottom bags.

Other Uses: Discarded cement bags can be transformed into creative items such as flower pots.

Packaging Information Labeling

Each bag of cement must be labeled with key information such as the type, strength grade, production date, and net weight, serving as a "ID card" for quality traceability.

PRODUCTION PROCESS

It has 4 high-speed electronic axis printing production lines of international brands such as BOBST and Otmar, with a printing speed of up to 400 meters per minute and 10 printing colors, which can meet the printing quality requirements of different customers. It is also equipped with dry and solvent-free composite equipment to meet the needs of customers with different functions. The finished product workshop is equipped with multiple high-speed slitting machines and various high-precision bag making machines, which can achieve 60 tons of film rolls and 5 million bags per day.

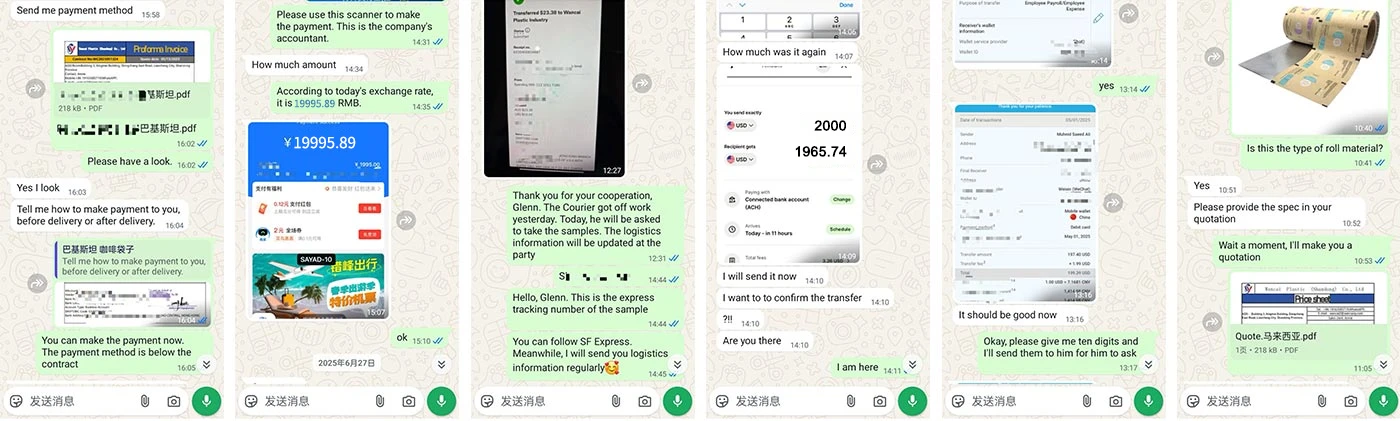

CASE

You can print up to 12 colors. As a zippered flat bag, the printing side can customize your artwork or provide your design drawings. SOME CUSTOM CASES Factory direct sales professional customization is trustworthy

CUSTOMER VISIT

You can print up to 12 colors. As a zippered flat bag, the printing side can customize your artwork or provide your design drawings. SOME CUSTOM CASES Factory direct sales professional customization is trustworthy

PACKING AND DELIVERY

The company strictly implements the PDCA cycle improvement management, constantly adopts scientific management models, adheres to the production concept of continuous improvement, pursues "excellent quality, zero defects" as the goal, and provides consumers with high-quality and stable flexible packaging products.

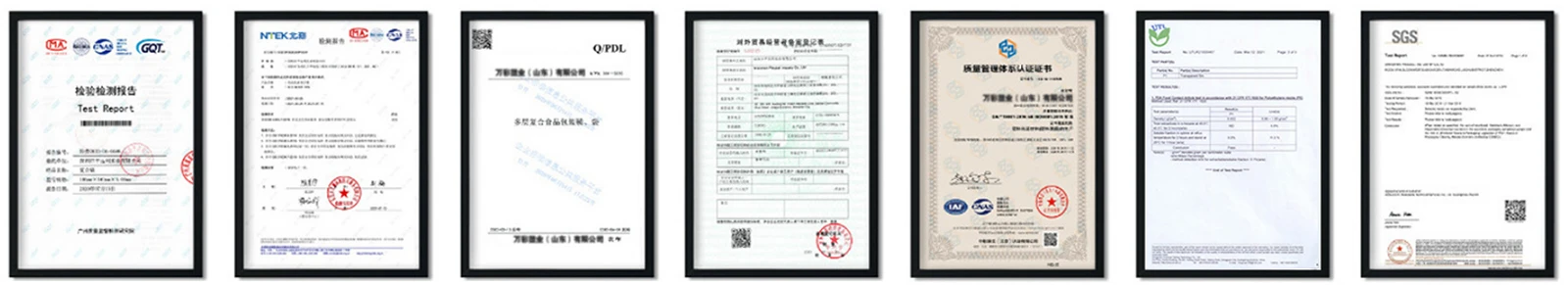

QUALIFICATIONS AND HONORS

we have management system that meets international requirements, issupervised and evaluated by third-party institutions,and is internationallyrecognized,providing more security for enterprises and escorting yourproducts.

Previous:

Related Products

Get Quote

*Contact us now, starting from the first communication!