Aluminum Packaging Film Roll

Category:

Keywords:

Semi-finished Packaging Materials

The composite in composite flexible packaging materials actually means lamination, which is to bond films or other flexible materials of different properties together, and then seal them to carry, protect and decorate the contents. The laminated structure of flexible packaging can be classified in many forms according to different combinations. However, conventional structures are usually distinguished by outer layer, middle layer, inner layer, adhesive layer, etc.

(I) Outer layer materials

The outer layer materials are usually selected from materials with good mechanical strength, heat resistance, good printing performance, and good optical properties. The most commonly used are polyester (PET), nylon (NY), stretched polypropylene (BOPP), paper and other materials.

Requirements and functions of outer layer materials

The middle layer materials are usually used to enhance a certain characteristic of the composite structure, such as barrier properties, light-shielding properties, fragrance retention, strength and other characteristics. The most commonly used are aluminum foil (AL), aluminized film (VMCPP, VMPET), polyester (PET), nylon (NY), polyvinylidene chloride coated film (KBOPP, KPET, KONY), EVOH and other materials.

(III) Inner layer material

The most critical function of the inner layer material is sealing. The inner layer structure is in direct contact with the inner object, so it is required to be non-toxic, odorless, water-resistant and oil-resistant. Commonly used materials are cast polypropylene (CPP), ethylene-vinyl acetate copolymer (EVA), polyethylene (PE) and its modified materials.

(IV) Adhesive layer

The function of the adhesive layer is to bond two adjacent layers of materials together to form a composite structure. According to the characteristics of the adjacent materials and the composite process, adhesives or adhesive resins can be used as adhesive layer materials. The bonding strength between the adhesive layer and the bonded materials is an important indicator for evaluating the intrinsic performance of composite packaging materials. Different packaging requirements have different requirements for this indicator.

Product features

The product has high barrier properties, oil resistance, light blocking, fragrance preservation, and freshness preservation. It can be customized according to the size of the product. The delivery cycle is shorter than bag making and the cost is lower than bag making. The product meets environmental protection requirements, with a new printing process that highlights pattern design and trademark effects. Special trademarks or patterns can be designed to achieve a good anti-counterfeiting effect. It can better highlight the high-end and unique shelf effect of the product.

·Specifications and sizes: Made according to the actual needs of customers

·Use distribution: Suitable for various automatic packaging machinery, products include food, daily chemicals, medicine, electronics, hardware parts and other industrial packaging.

·Packaging type: roll film

·Contents: milk film, food packaging film

·Material combination: polyester (PET), nylon (NY), oriented polypropylene (BOPP), paper, aluminum foil (AL), aluminized film (VMCPP, VMPET), polyester (PET), nylon (NY), polyvinylidene chloride coated film (KBOPP, KPET, KONY), EVOH, cast polypropylene (CPP), ethylene-vinyl acetate copolymer (EVA), polyethylene (PE) and its modified materials, etc.

PRODUCTION PROCESS

It has 4 high-speed electronic axis printing production lines of international brands such as BOBST and Otmar, with a printing speed of up to 400 meters per minute and 10 printing colors, which can meet the printing quality requirements of different customers. It is also equipped with dry and solvent-free composite equipment to meet the needs of customers with different functions. The finished product workshop is equipped with multiple high-speed slitting machines and various high-precision bag making machines, which can achieve 60 tons of film rolls and 5 million bags per day.

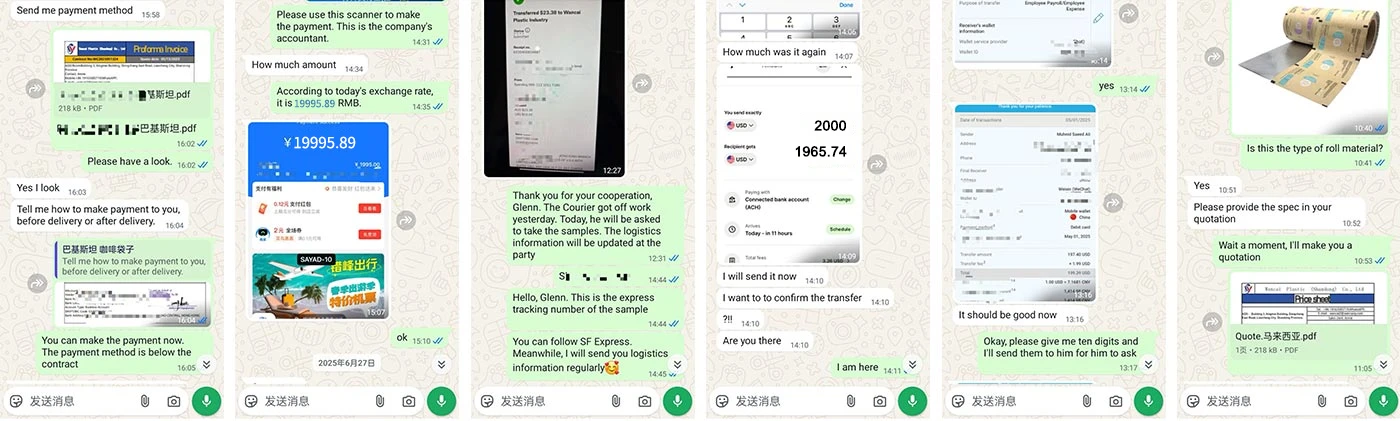

CASE

You can print up to 12 colors. As a zippered flat bag, the printing side can customize your artwork or provide your design drawings. SOME CUSTOM CASES Factory direct sales professional customization is trustworthy

CUSTOMER VISIT

You can print up to 12 colors. As a zippered flat bag, the printing side can customize your artwork or provide your design drawings. SOME CUSTOM CASES Factory direct sales professional customization is trustworthy

PACKING AND DELIVERY

The company strictly implements the PDCA cycle improvement management, constantly adopts scientific management models, adheres to the production concept of continuous improvement, pursues "excellent quality, zero defects" as the goal, and provides consumers with high-quality and stable flexible packaging products.

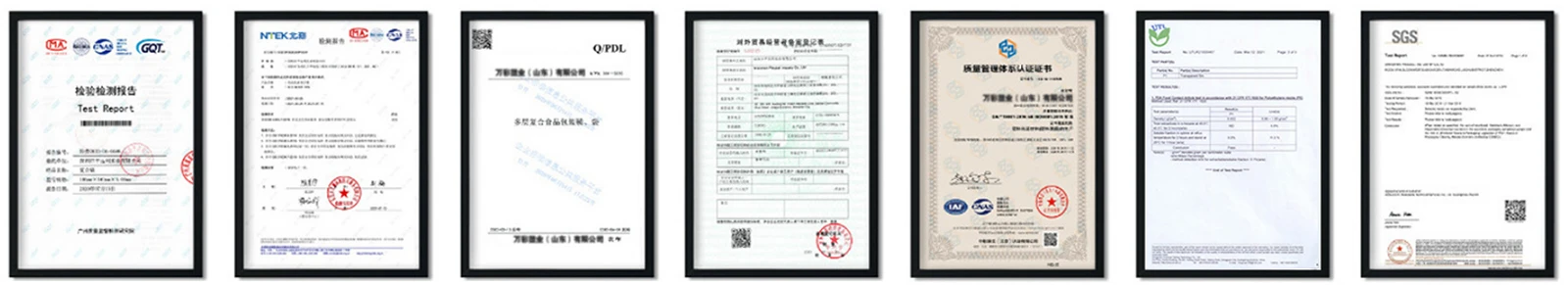

QUALIFICATIONS AND HONORS

we have management system that meets international requirements, issupervised and evaluated by third-party institutions,and is internationallyrecognized,providing more security for enterprises and escorting yourproducts.

Previous:

Next:

Related Products

Get Quote

*Contact us now, starting from the first communication!