Aluminum Foil Coffee Bag

Category:

Keywords:

Food Packaging

Aluminum foil bags are also called pure aluminum bags

Thickness: 70-180 microns Bag shape: three-side seal, self-supporting zipper bag, yin-yang bag

Features: PET-biaxially oriented polyester film, NY-biaxially oriented polyamide film, AL-aluminum foil, PE-polyethylene (collectively, there are 5 different categories), CPP-cast polypropylene film

Aluminum foil bags (anti-static aluminum foil bags, aluminum foil packaging bags), product features Appearance: opaque, silvery white, with anti-gloss, good barrier properties, heat sealing, light-shielding, high temperature resistance, low temperature resistance, oil resistance, fragrance retention; non-toxic and tasteless; soft and other characteristics. Product structure:

PET/AL/PET/PE. Products of different composite materials and thicknesses can be customized as required. Storage environment temperature ≤38℃, humidity ≤90% 5. Conventional product specifications: thickness 0.10mm and 0.14mm, three-side seal, edge seal 10mm, product specifications and sizes can be customized according to customer needs.

Application

(1) Suitable for packaging of various circuit boards, electronic products, precision machinery parts, consumer goods, industrial products, etc. For example: PC boards, IC integrated circuits, electronic components, SMT patches of various LED industries, light strip packaging, precision hardware, auto parts, etc.

(2) Packaging type: suitable for all bag types.

(3) Contents: coffee, cooking bags, raw/cooked meat products, grains, etc.

(4) Material combination ①BOPA+LDPE; ②PET+LDPE; ③BOPA+RCPP; ④PET+BOPA+RCPP; ⑤BOPP+VMPET+LDPE; ⑥PET+AL+BOPA+LDPE; ⑦Customization

Features

(1) Strong air barrier performance, anti-oxidation, waterproof and moisture-proof.

(2) Strong mechanical properties, high anti-blasting performance, strong anti-puncture and tearing performance.

(3) High temperature resistance (121℃), low temperature resistance (-50℃), oil resistance, and good aroma retention performance.

(4) Non-toxic and tasteless, in line with food and drug packaging hygiene standards.

(5) Good heat sealing performance, softness, and high barrier properties.

PRODUCTION PROCESS

It has 4 high-speed electronic axis printing production lines of international brands such as BOBST and Otmar, with a printing speed of up to 400 meters per minute and 10 printing colors, which can meet the printing quality requirements of different customers. It is also equipped with dry and solvent-free composite equipment to meet the needs of customers with different functions. The finished product workshop is equipped with multiple high-speed slitting machines and various high-precision bag making machines, which can achieve 60 tons of film rolls and 5 million bags per day.

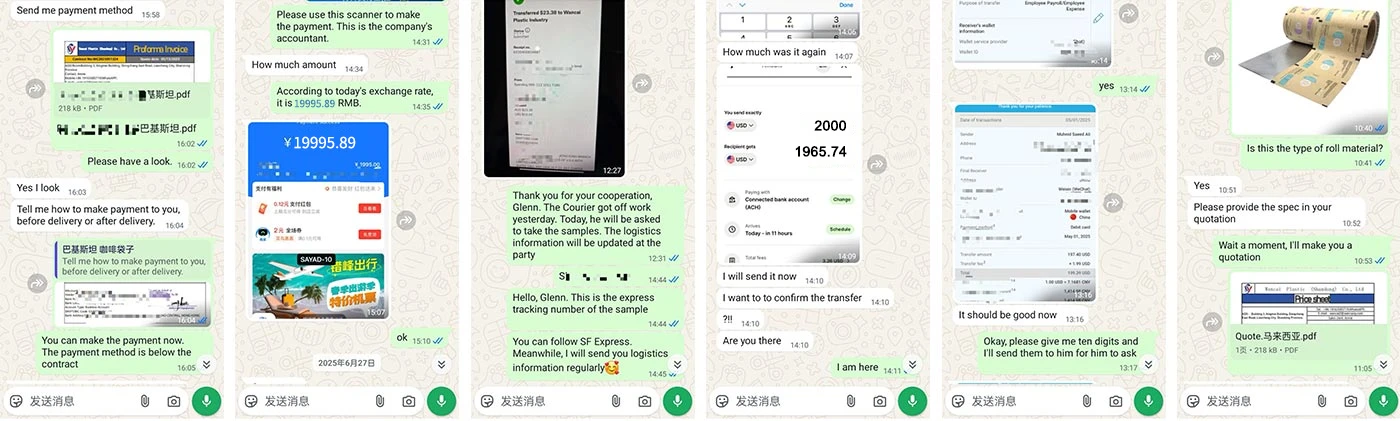

CASE

You can print up to 12 colors. As a zippered flat bag, the printing side can customize your artwork or provide your design drawings. SOME CUSTOM CASES Factory direct sales professional customization is trustworthy

CUSTOMER VISIT

You can print up to 12 colors. As a zippered flat bag, the printing side can customize your artwork or provide your design drawings. SOME CUSTOM CASES Factory direct sales professional customization is trustworthy

PACKING AND DELIVERY

The company strictly implements the PDCA cycle improvement management, constantly adopts scientific management models, adheres to the production concept of continuous improvement, pursues "excellent quality, zero defects" as the goal, and provides consumers with high-quality and stable flexible packaging products.

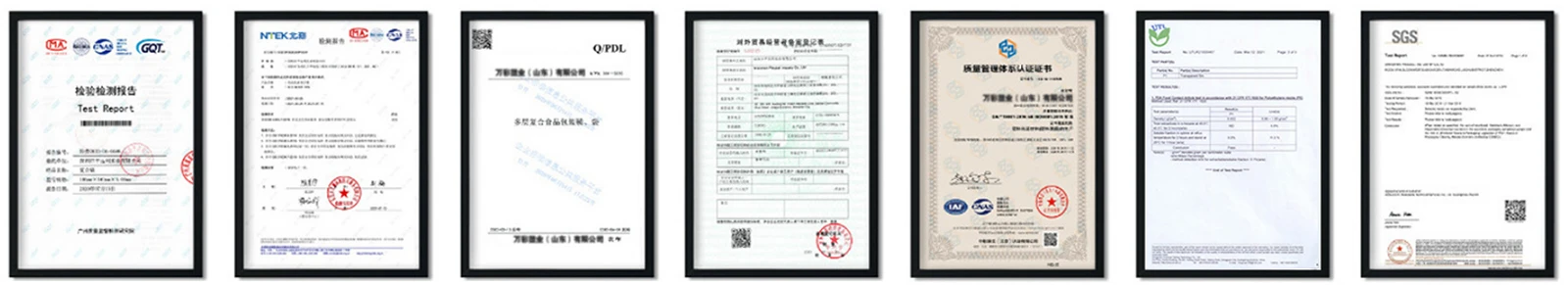

QUALIFICATIONS AND HONORS

we have management system that meets international requirements, issupervised and evaluated by third-party institutions,and is internationallyrecognized,providing more security for enterprises and escorting yourproducts.

Previous:

Related Products

Get Quote

*Contact us now, starting from the first communication!